Index

Energy Solutions

The energy-efficient operation of technical systems is of increasing importance in view of global warming and the transition to renewable energies. Control systems engineering has a high potential to contribute to the efficient use of energy, for example, regarding energy consumption of buildings, energy conversion and storage, as well as power grids. Our research in terms of optimization and learning-based control methods forms the ideal basis to develop sustainable solutions in energy-related applications.

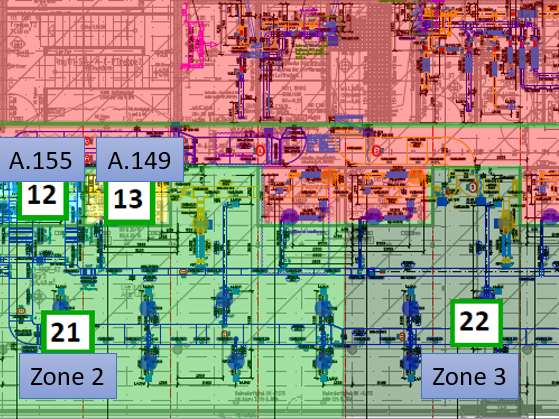

The efficient and sustainable use of energy is one of the grand challenges today. Control engineering is a key technology to accomplish this goal by providing tailored automation solutions. For instance, heating, ventilation and air conditioning (HVAC) systems in residential and non-residential buildings belong to the largest energy consumers. Advanced control schemes can help to efficiently control HVAC systems while learning the building characteristics like thermal dynamics or room occupancy patterns and considering stochastic weather forecasts to reduce the energy consumption in a predictive manner.

Another example are electrical grids that connect energy sources (power plants, wind turbines, etc.) and energy sinks (e.g. factories, households). On the lower level, each involved component, e.g. drives and inverters, can be designed to reduce undesired power dissipation. On the higher level, the energy distribution itself can be optimized using, for instance, distributed model predictive control for smart grids.

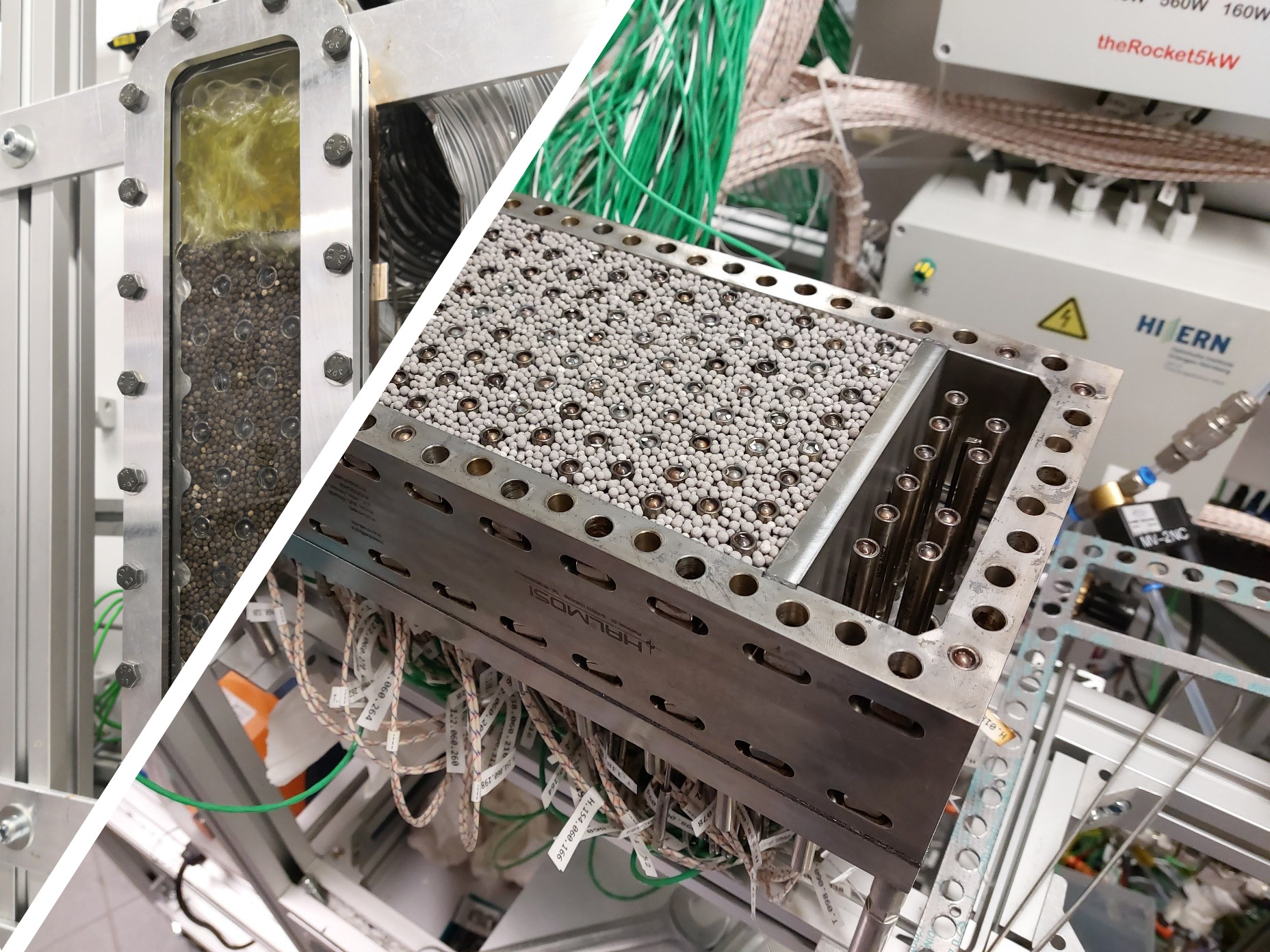

Despite the current prevalence of batteries as mobile energy storages, hydrogen-based fuel cells are a promising alternative for applications with high energy demand as, for example, trains or ships. One option to solve the problem of save hydrogen storage is the use of liquid organic hydrogen carriers (LOHC), either as storage/transport medium or for direct fuel cell usage. The de-/hydrogenation of LOHC is a complex process that offers high potential for improvement by modern control methods.

Related projects since 2021

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Bundesministerium für Wirtschaft und Energie (BMWE)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

To achieve climate targets, CO2 emissions in the building sector have to be significantly reduced. However, the integration of renewable energy sources increases the complexity of building energy systems and thus the requirements for the operation strategy. Model-based and predictive controllers are necessary for efficient operation. However, due to the high complexity of the energy systems, the development, implementation, and commissioning are very complex leading to high costs, which is why model…

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Helmholtz-Gemeinschaft

Project leader: ,

Prof. Dr.-Ing. Knut Graichen

Chair holder

Related publications

- Kowalewski J, Lorenz A, Thomas F, Valenzuela RAA, Graichen K (2025). Passivity-Based Robust Stability Analysis of the Converter–Grid Interaction and Passivity-Shaping Controller Design. IET Generation Transmission & Distribution, 19(1). [DOI].

- Landgraf D, Wietzke T, Graichen K (2025). Stochastic model predictive control with switched latent force models. In European Control Conference (pp. 101311). European Journal of Control, 85, 101311. [DOI].

- Schumann M, Ebersberger S, Graichen K (2023). Online learning and adaptation of nonlinear thermal networks for power inverters. In 49th Annual Conference of the IEEE Industrial Electronics Society (IECON 2023).

- Schumann M, Ebersberger S, Graichen K (2023). Improved nonlinear estimation in thermal networks using machine learning. In IEEE International Conference on Mechatronics (ICM 2023). [DOI].

- Verhoolen A, Geißelbrecht M, Kadar J, Preuster P, Wasserscheid P, Graichen K (2024). Bayesian optimization of operating points of a continuous perhydro-dibenzyltoluene dehydrogenation reactor. International Journal of Energy Research. [DOI].

- Wietzke T, Gall J, Graichen K (2024). Occupancy Prediction for Building Energy Systems with Latent Force Models. Energy and Buildings, pp. 113968. [DOI].

- Wietzke T, Graichen K (2025). Physics-informed sparse Gaussian processes for model predictive control in building energy systems. In 11th Vienna International Conference on Mathematical Modelling (MATHMOD 25) (pp. 43-48). [DOI].

- Wietzke T, Landgraf D, Graichen K (2025). Application of stochastic model predictive control for building energy systems using latent force models. At-Automatisierungstechnik, 73(6), 441-450. [DOI].

- Huber H, Burk D, Graichen K (2022). Comparison of sensitivity-based and ADMM-based DMPC applied to building automation. In 6th IEEE Conference on Control Technology and Applications (CCTA) (pp. 546-553). [DOI].

- Kowalewski J, Lorenz A, Lomakin A, Alvarez R, Graichen K (2022). Circulating current control and energy balancing of a modular multilevel converter using model predictive control for HVDC applications. In 48th Annual Conference of the IEEE Industrial Electronics Society (IECON 2022). [DOI].

- Schumann M, Ebersberger S, Graichen K (2022). Dynamic and stationary state estimation of fluid cooled three-phase inverters. In 26th IEEE International Symposium on Power Electronics, Electrical Drives Automation and Motion (SPEEDAM 2022). [DOI].

- Huber H, Graichen K (2021). A sensitivity-based distributed model predictive control algorithm for nonlinear continuous-time systems. In 5th IEEE Conference on Control Technology and Applications (CCTA) (pp. (accepted)). [DOI].

Learning in Control

Algorithms of artificial intelligence and machine learning are of increasing importance for control applications. Our research and expertise in this domain ranges from the modeling of unknown or uncertain dynamics over iterative and reinforcement learning to Bayesian optimization.

One research focus at the Chair is on learning in model design and identification. Hybrid and data-driven models are attractive if physical modeling is either poor or requires high effort. Practical applications often require an online adaptation of these models in order to reflect effects of aging or wear or to increase the model accuracy in different operation regimes. Information about the reliability and trustworthiness of a learned model can directly be used within the control design. For instance, the prediction of the uncertainty allows to satisfy constraints with a given probability. A challenge with learning-based methods is to ensure real-time feasibility with possibly weak hardware resources in order to bring these advanced learning in control methods into practice.

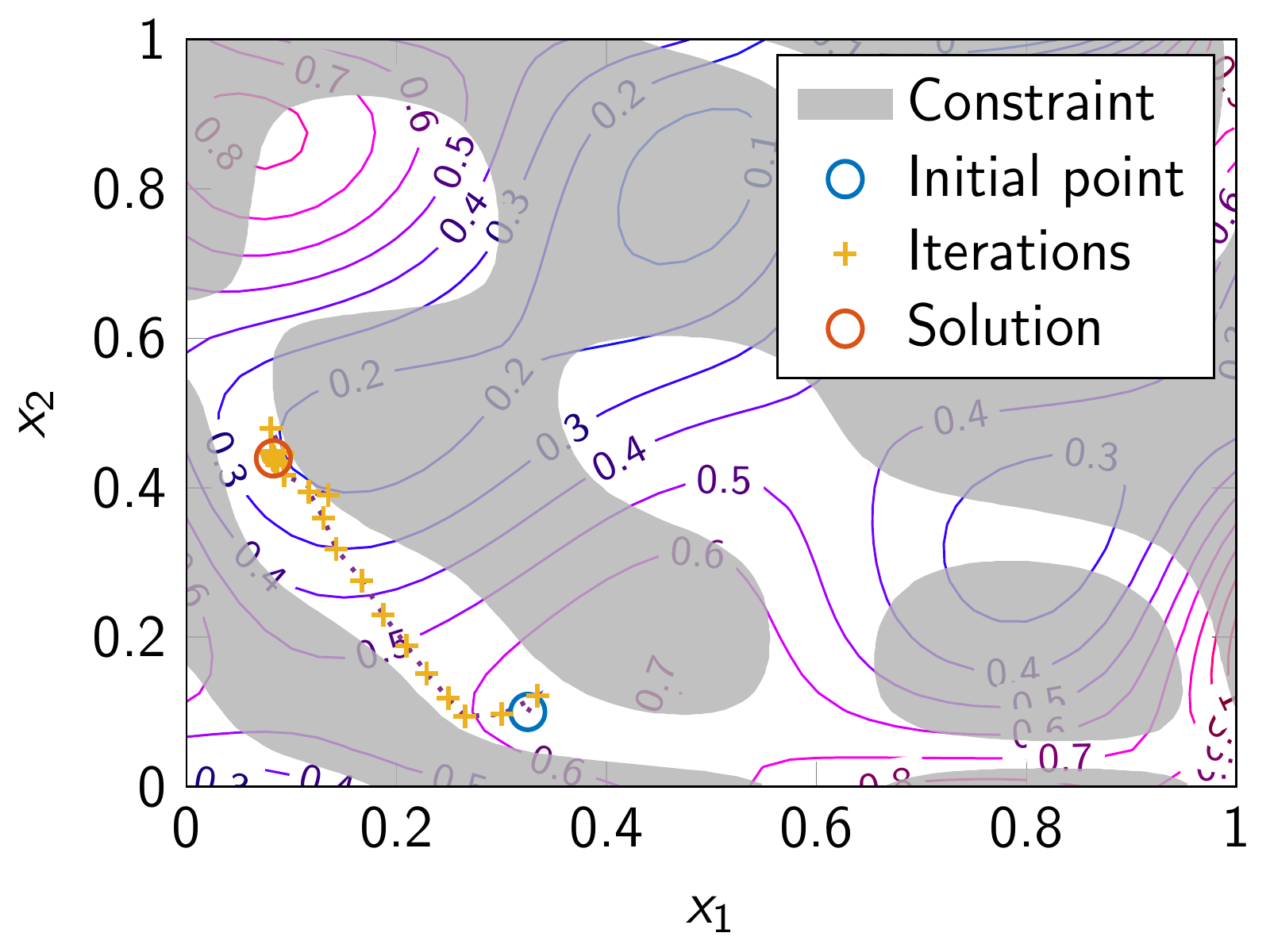

Another field of research and expertise is learning in optimization and control, for instance, reinforcement learning and Bayesian optimization. Reinforcement learning aims at obtaining an optimal control strategy from repeated interactions with the system. Formulating this task as an optimization problem shows the conceptual similarity to model predictive control, with the difference that reinforcement learning does not require model knowledge of the system. In a similar spirit, Bayesian optimization allows to solve complex optimization problem, in particular if the cost function or constraints are not analytically known or can only be evaluated by costly numerical simulations. Many technical tasks such as the optimization of production processes, an optimal product design or the search of optimal controller setpoints can be formulated as (partially) unknown optimization problem, illustrating the generality and importance of Bayesian optimization.

Related projects since 2021

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Deutsche Forschungsgemeinschaft (DFG)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

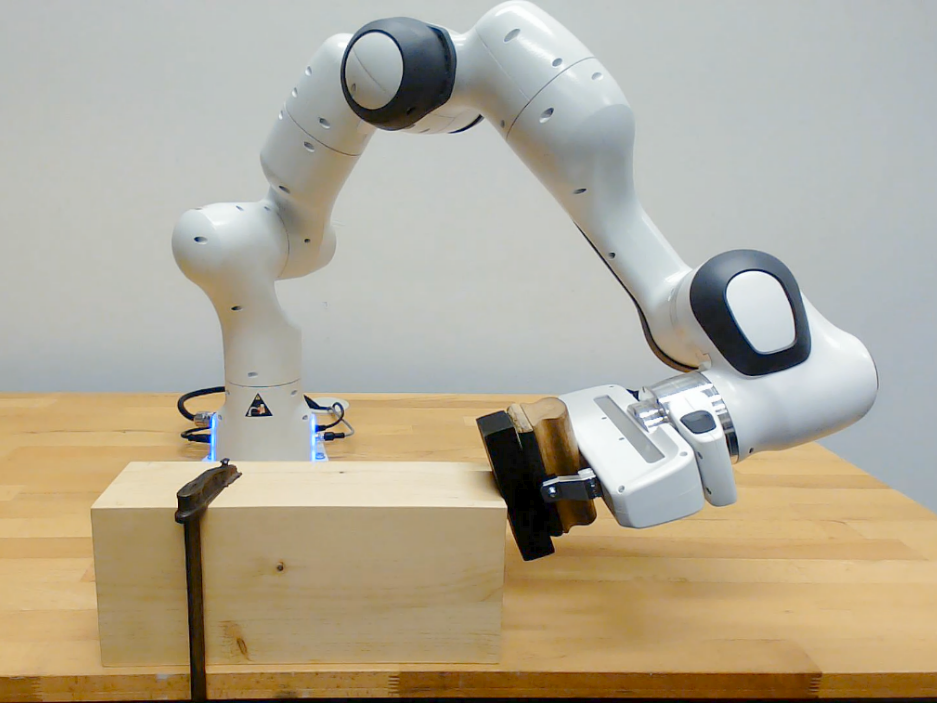

Precise interactions as part of industrial manufacturing tasks are typically very complex to characterize and implement. One reason for this is the heterogeneity of the task-specific requirements for the motion and control behavior. A direct implementation of the task into a robot program therefore requires highly qualified specialists and is only profitable for large lot sizes. For a flexible applicability and easy (re-)configuration of the robot system, an approach to programming by kinesthetic…

Funding source: Bundesministerium für Wirtschaft und Energie (BMWE)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

To achieve climate targets, CO2 emissions in the building sector have to be significantly reduced. However, the integration of renewable energy sources increases the complexity of building energy systems and thus the requirements for the operation strategy. Model-based and predictive controllers are necessary for efficient operation. However, due to the high complexity of the energy systems, the development, implementation, and commissioning are very complex leading to high costs, which is why model…

Funding source: Bundesministerium für Forschung, Technologie und Raumfahrt (BMFTR)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Bundesministerium für Wirtschaft und Energie (BMWE)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Related publications

- Conrad P, Graichen K (2024). A sensitivity-based approach to self-triggered nonlinear model predictive control. IEEE Access, 12, 153243-153252. [DOI].

- Conrad P, Steuter L, Pierer von Esch M, Beck J, Graichen K (2025). Aerodynamic neural network modeling for gradient-based model predictive flight control. In 33rd Mediterranean Conference on Control and Automation (MED 2025).

- Dio M, Demir O, Trachte A, Graichen K (2023). Safe active learning and probabilistic design of experiment for autonomous hydraulic excavators. In 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 9685-9690).

- Goller T, Brohm D, Völz A, Graichen K (2024). DMP-based path planning for model predictive interaction control. In European Control Conference (pp. 128-133).

- Goller T, Hopf V, Völz A, Graichen K (2025). Fault Handling in Robotic Manipulation Tasks for Model Predictive Interaction Control. IEEE Robotics and Automation Letters, 10(9), 9002 – 9009. [DOI].

- Goller T, Völz A, Graichen K (2024). A Programming by Demonstration Approach for Robotic Manipulation with Model Predictive Interaction Control. In 2024 IEEE Conference on Control Technology and Applications (CCTA) (pp. 799-804).

- Hartmann P, Graichen K (2025). Learning-based uncertainty-aware predictive control of truck-trailer systems in rough terrain. In 19th IEEE International Conference on Control & Automation (ICCA).

- Hoffmann M, Braun S, Sura O, Stelzig M, Schüßler C, Graichen K, Vossiek M (2023). Concept for an Automatic Annotation of Automotive Radar Data Using AI-segmented Aerial Camera Images. In 2023 IEEE International Radar Conference, RADAR 2023. [DOI].

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2025). Estimation of input rotation speed in gauge-sensorized strain wave gears. In 2025 IEEE Conference on Control Technology and Applications (CCTA).

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2024). Fault detection in gauge-sensorized strain wave gears. In European Control Conference (pp. 26-33). [DOI].

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2025). Model-based fault simulation and detection for gauge-sensorized strain wave gears. In 11th Vienna International Conference on Mathematical Modelling (MATHMOD 25) (pp. 271 – 276). [DOI].

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2023). Simulation chain for sensorized strain wave gears. In 27th International Conference on System Theory, Control and Computing (ICSTCC) (pp. 467 – 473). [DOI].

- Landgraf D, Völz A, Berkel F, Schmidt K, Specker T, Graichen K (2023). Probabilistic prediction methods for nonlinear systems with application to stochastic model predictive control. Annual Reviews in Control, 56, 100905. [DOI].

- Landgraf D, Völz A, Graichen K (2025). A software framework for stochastic model predictive control of nonlinear continuous-time systems (GRAMPC-S). Optimization and Engineering. [DOI].

- Landgraf D, Wietzke T, Graichen K (2025). Stochastic model predictive control with switched latent force models. In European Control Conference (pp. 101311). European Journal of Control, 85, 101311. [DOI].

- Rabenstein G, Ullrich L, Graichen K (2024). Sampling for model predictive trajectory planning in autonomous driving using normalizing flows. In 35th IEEE Intelligent Vehicles Symposium (IEEE IV 2024) (pp. 2091-2096).

- Santer P, Völz A, Graichen K (2025). A Model Predictive Control Approach to Trajectory Tracking with Human-Robot Collision Avoidance. In 2025 IEEE Conference on Control Technology and Applications (CCTA).

- Schumann M, Ebersberger S, Graichen K (2023). Online learning and adaptation of nonlinear thermal networks for power inverters. In 49th Annual Conference of the IEEE Industrial Electronics Society (IECON 2023).

- Schumann M, Ebersberger S, Graichen K (2023). Improved nonlinear estimation in thermal networks using machine learning. In IEEE International Conference on Mechatronics (ICM 2023). [DOI].

- Schumann M, Graichen K (2024). PINN-based dynamical modeling and state estimation in power inverters. In 2024 IEEE Conference on Control Technology and Applications (CCTA).

- Snobar F, Michalka A, Horn M, Strohmeyer C, Graichen K (2023). Rack force estimation from standstill to high speeds by hybrid model design and blending. In IEEE International Conference on Mechatronics (ICM 2023). [DOI].

- Snobar F, Michalka A, Horn M, Strohmeyer C, Graichen K (2024). Sensitivity-based moving horizon estimation of road friction. In European Control Conference (pp. 718-724).

- Spenger P, Graichen K (2023). Performance prediction of NMPC algorithms with incomplete optimization. In 22nd IFAC World Congress (pp. 7456-7461).

- Stecher J, Kiltz L, Graichen K (2025). Generalized tolerance optimization for robust system design by adaptive learning of Gaussian processes. IEEE Access, (accepted).

- Ullrich L, Buchholz M, Dietmayer K, Graichen K (2024). AI safety assurance for automated vehicles: A survey on research, standardization, regulation. IEEE Transactions on Intelligent Vehicles. [DOI].

- Ullrich L, Buchholz M, Dietmayer K, Graichen K (2024). Expanding the Classical V-Model for the Development of Complex Systems Incorporating AI. IEEE Transactions on Intelligent Vehicles. [DOI].

- Ullrich L, Buchholz M, Petit J, Dietmayer K, Graichen K (2025). A Concept for Efficient Scalability of Automated Driving Allowing for Technical, Legal, Cultural, and Ethical Differences. In 2025 IEEE 28th International Conference on Intelligent Transportation Systems (ITSC).

- Ullrich L, McMaster A, Graichen K (2024). Transfer learning study of motion transformer based trajectory predictions. In 35th IEEE Intelligent Vehicles Symposium (IEEE IV 2024) (pp. 110-117).

- Ullrich L, Mujirishvili Z, Graichen K (2025). Enhancing system self-awareness and trust of AI: A case study in trajectory prediction and planning. In 36th IEEE Intelligent Vehicles Symposium (IEEE IV 2025).

- Ullrich L, Völz A, Graichen K (2023). Robust meta-learning of vehicle yaw rate dynamics via conditional neural processes. In 62nd IEEE Conference on Decision and Control (CDC) (pp. 322-327).

- Ullrich L, Zimmer W, Greer R, Graichen K, Knoll AC, Trivedi M (2025). A New Perspective On AI Safety Through Control Theory Methodologies. IEEE Open Journal of Intelligent Transportation Systems, 6, 938-966. [DOI].

- Wietzke T, Gall J, Graichen K (2024). Occupancy Prediction for Building Energy Systems with Latent Force Models. Energy and Buildings, pp. 113968. [DOI].

- Wietzke T, Graichen K (2025). Physics-informed sparse Gaussian processes for model predictive control in building energy systems. In 11th Vienna International Conference on Mathematical Modelling (MATHMOD 25) (pp. 43-48). [DOI].

- Wietzke T, Landgraf D, Graichen K (2025). Application of stochastic model predictive control for building energy systems using latent force models. At-Automatisierungstechnik, 73(6), 441-450. [DOI].

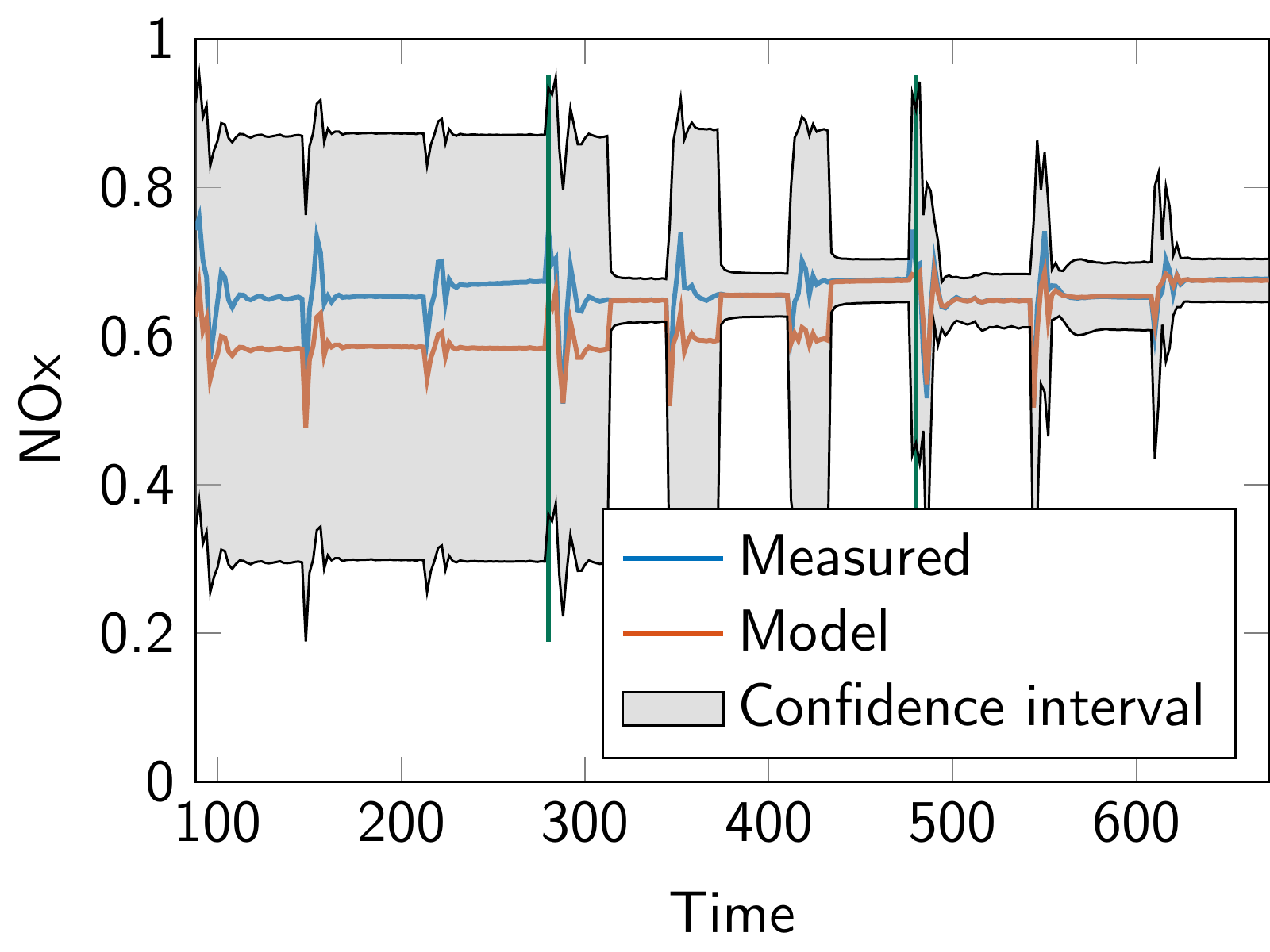

- Bergmann D, Harder K, Niemeyer J, Graichen K (2022). Nonlinear MPC of a Heavy-Duty Diesel Engine With Learning Gaussian Process Regression. IEEE Transactions on Control Systems Technology, 30(1), 113-129. [DOI].

- Goller T, Gold T, Völz A, Graichen K (2022). Model predictive interaction control based on a path-following formulation. In Proceedings IEEE International Conference on Mechatronics and Automation (ICMA) (pp. 551-556). [DOI].

- Landgraf D, Völz A, Kontes G, Graichen K, Mutschler C (2022). Hierarchical learning for model predictive collision avoidance. In 10th Vienna International Conference on Mathematical Modelling (MATHMOD 22) (pp. 355-360). [DOI].

- Rabenstein G, Demir O, Trachte A, Graichen K (2022). Data-driven feed-forward control of hydraulic cylinders using Gaussian process regression for excavator assistance functions. In 6th IEEE Conference on Control Technology and Applications (CCTA) (pp. 962-969). [DOI].

- Schumann M, Ebersberger S, Graichen K (2022). Dynamic and stationary state estimation of fluid cooled three-phase inverters. In 26th IEEE International Symposium on Power Electronics, Electrical Drives Automation and Motion (SPEEDAM 2022). [DOI].

- Stecher J, Kiltz L, Graichen K (2022). Semi-infinite programming using Gaussian process regression for robust design optimization. In Proceedings European Control Conference (pp. 52-59). [DOI].

- Bergmann D, Graichen K (2020). Safe Bayesian Optimization under Unknown Constraints. In 59th IEEE Conference on Decision and Control, CDC 2020 (pp. 3592-3597). [DOI].

- Geiselhart R, Bergmann D, Niemeyer J, Remele J, Graichen K (2020). Hierarchical Predictive Control of a Combined Engine/Selective Catalytic Reduction System with Limited Model Knowledge. SAE International Journal of Engines, 13(2). [DOI].

- Geiselhart R, Bergmann D, Niemeyer J, Remele J, Graichen K (2020). Hierarchical predictive control of a combined engine/SCR system with limited model knowledge. SAE International Journal of Engines, 13(2). [DOI].

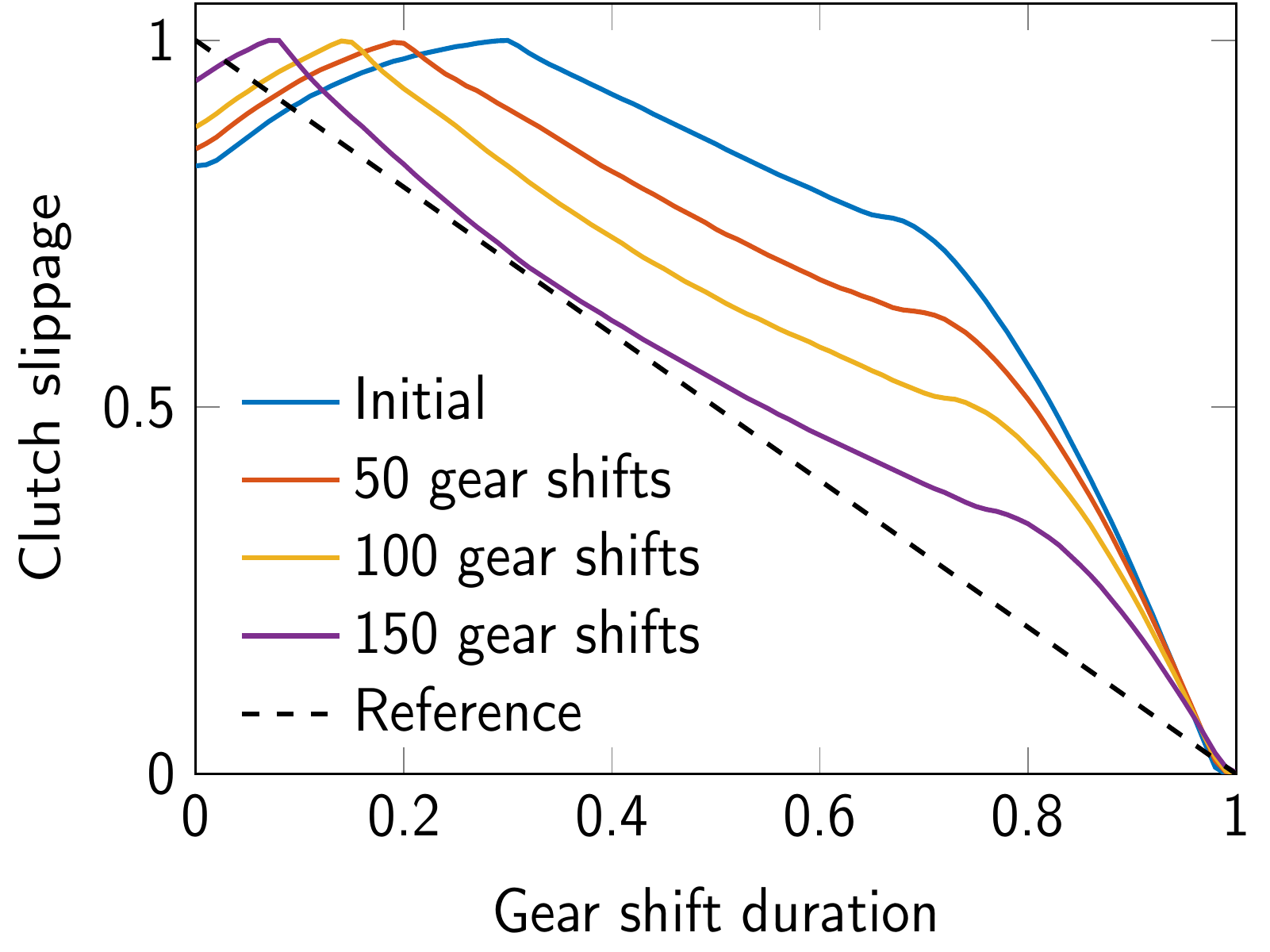

- Mesmer F, Szabo T, Graichen K (2020). Learning feedforward control of a hydraulic clutch actuation path based on policy gradients. In 59th IEEE Conference on Decision and Control (CDC 2020). [DOI].

- Bergmann D, Geiselhart R, Graichen K (2019). Modelling and control of a heavy-duty Diesel engine gas path with Gaussian process regression. In Proc. European Control Conference (ECC 2019) (pp. 1207-1213). Naples (Italy). [DOI].

- Bergmann D, Graichen K (2019). Gaußprozessregression zur Modellierung zeitvarianter Systeme. At-Automatisierungstechnik, 67(8), 637-647. [DOI].

- Mesmer F, Szabo T, Graichen K (2019). Learning methods for the feedforward control of a hydraulic clutch actuation path. In Proc. IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM 2019) (pp. 733-738). Hong Kong (China). [DOI].

Control & Optimization

The development of control and optimization methods for dynamical systems is the natural research focus of the Chair of Automatic Control. In particular, we focus on nonlinear and predictive control concepts as well as path/trajectory planning for dynamical systems closely related to optimization-based methods, always having an eye on the real-time and embedded realization for practical applications.

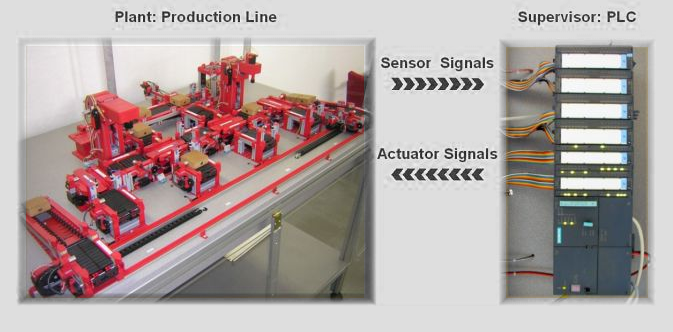

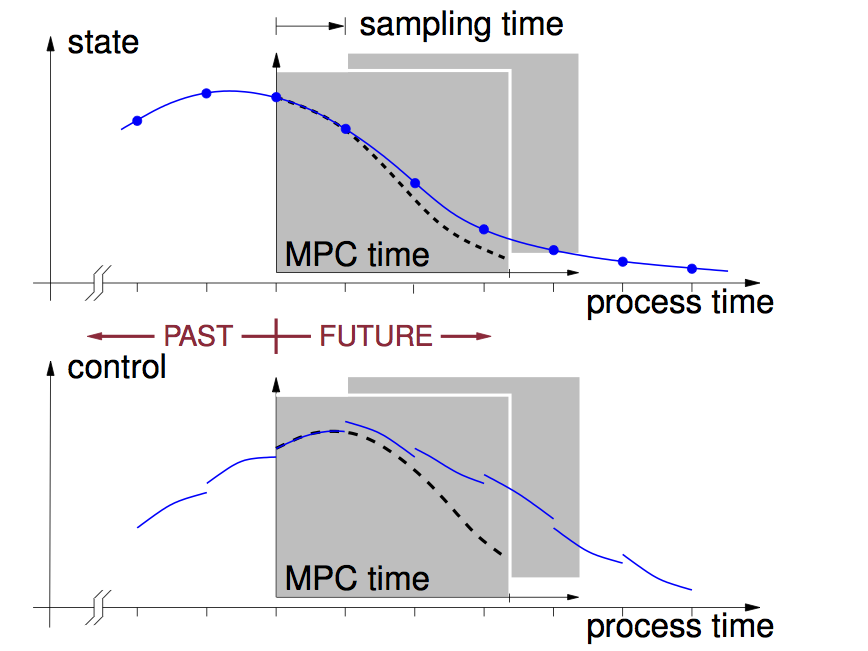

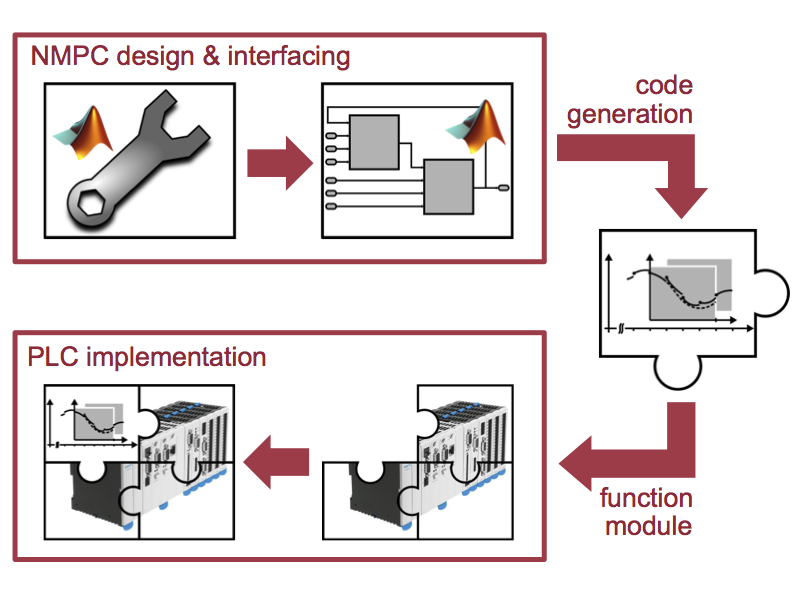

Research on nonlinear systems and control is at the heart of the Chair of Automatic Control. Modern control concepts such as model predictive control (MPC) often rely on optimization problems that have to be solved online. In particular mechatronic systems often require sampling times in the (sub-)millisecond range and therefore highly efficient control algorithms and warm-start strategies. The Chair of Automatic Control has long standing experience with the modeling of control problems of different physical domains and the development of nonlinear and predictive control concepts, always with the intention to bring these methods into practice. We also develop and maintain the open source MPC toolbox GRAMPC that was successfully used in many research and industrial projects and by other research groups. Current research concerns the extension to stochastic nonlinear systems to account for uncertainties in a consistent probabilistic setting.

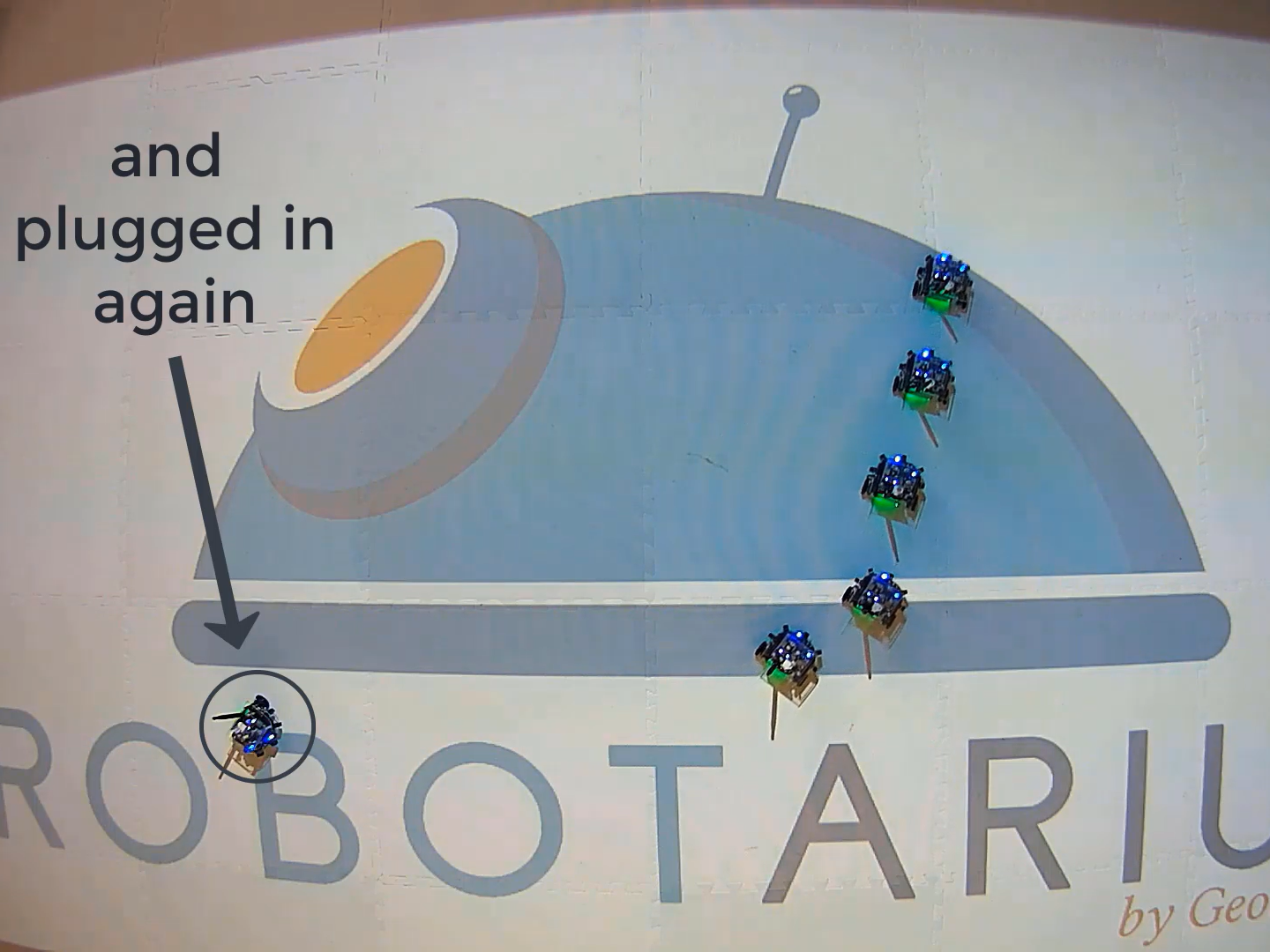

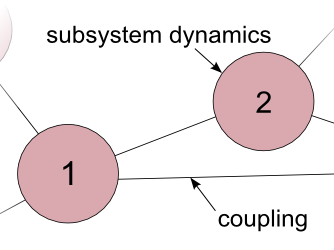

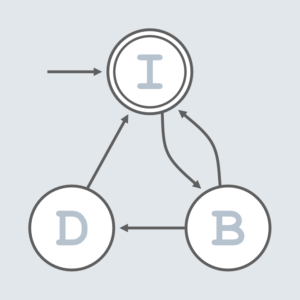

Beyond the “classical” centralized view on control applications, networked systems are of increasing importance, not only in terms of autonomous and mobile robots, distributed energy networks (smart grids), but also in connection with industry 4.0 and flexible production. The control of networked systems is challenging, because centralized approaches do not scale well with the number of subsystems and do not provide the flexibility for plug-and-play or reconfiguration scenarios. We focus on both the design of distributed (model predictive) control schemes for networked systems as well as the agent-based distributed implementation of these concepts along with suitable communication concepts to enhance the overall efficiency of networked systems. An outcome of this research is the open-source framework GRAMPC-D that implements a real-time efficient ADMM algorithm for distributed model predictive control of nonlinear networked systems including plug-and-play functionality.

Videos

Related projects since 2021

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Bayerische Forschungsstiftung

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: DFG-Einzelförderung / Sachbeihilfe (EIN-SBH)

Project leader:

Dr.-Ing. Andreas Völz

Senior Lecturer

Dual-armrobots offer a high potential for automation technology, as they canbe used to implement tasks that are not possible with one arm alone.This includes in particular the manipulation of large or heavyobjects that exceed the payload of a single arm. Illustrativeexamples are the movement of beverage crates, long boards or pipes,which are also preferably grasped by humans with both hands.

However,cooperative manipulation is particularly challenging, because botharms and the grasped object…

Funding source: Deutsche Forschungsgemeinschaft (DFG)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: DFG / Schwerpunktprogramm (SPP)

Project leader: , ,

Prof. Dr.-Ing. Knut Graichen

Chair holder

The aim of this project is the automated production of liquid-liquid disperse systems via melt emulsification, whereby in this process emulsification takes place at elevated temperature. The products obtained after cooling are dispersions of spherical nanoparticles or microparticles. Within the scope of this project, a melt emulsification device for the automated production of product particles with a well-defined particle size distribution (PSD) will be further developed. The PSD has a significant influence on the subsequent product properties, such as flow behavior or drug release kinetics. The PSD of the products is determined by the complex interaction of competing mechanisms. These are, in particular, droplet breakup in a rotor-stator device as a result of shear and elongation stress, as well as coalescence and further ripening, which in turn depend on the system composition, i.e. the emulsifier used (type, concentration) and the dispersion phase (viscosity, volume fraction).

Therefore, for a better process understanding and an active process control, possibilities for in situ determination of the PSD are urgently required. In this project, a novel fiber-coupled measurement system based on broadband elastic light scattering is developed for in situ measurement of the PSD. The system will be validated on reference particle systems and applied to the emulsification process. Furthermore, a hybrid process model is developed, which is the basis for the design of a model predictive control of the process. The model predictive control in combination with the in situ measurement will provide the possibility for an active process control and the production of emulsions with predefined properties and a simultaneous optimization of the process time.

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Related publications

- Cherian AJ, Michalka A, Murray K, Roell G, Graichen K (2024). Control approaches for operating point stabilization of microring resonator modulators under fast perturbations. In Silicon Photonics XIX (pp. 128910D). [DOI].

- Conrad P, Graichen K (2024). A sensitivity-based approach to self-triggered nonlinear model predictive control. IEEE Access, 12, 153243-153252. [DOI].

- Conrad P, Michalka A, Beck J, Graichen K (2025). Nonlinear MPC for Stabilizing the Longitudinal Dynamics of a Highly Maneuverable Aircraft. In IEEE Aerospace Conference. IEEE Aerospace Conference Proceedings.

- Conrad P, Steuter L, Pierer von Esch M, Beck J, Graichen K (2025). Aerodynamic neural network modeling for gradient-based model predictive flight control. In 33rd Mediterranean Conference on Control and Automation (MED 2025).

- Dahlmann J, Graichen K, Völz A (2024). Ein Konzept zum automatisierten Rangieren von Fahrzeugen mit Anhängern. At-Automatisierungstechnik, 72(4), 354-368. [DOI].

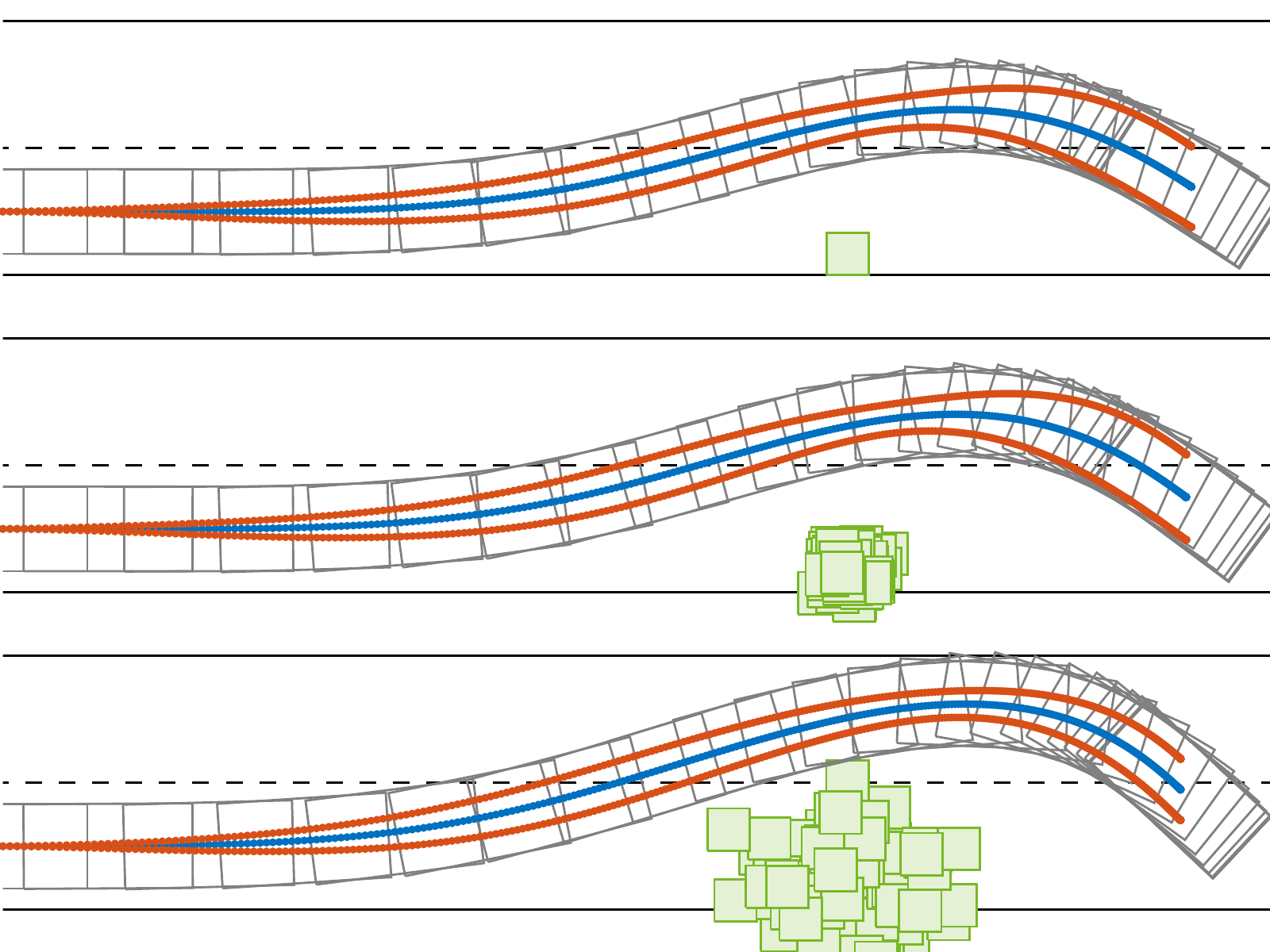

- Dahlmann J, Völz A, Lukassek M, Graichen K (2024). Local predictive optimization of globally planned motions for truck-trailer systems. IEEE Transactions on Control Systems Technology, 32(5), 1555-1568. [DOI].

- Dio M, Graichen K, Völz A (2024). Time-Optimal Path Parameterization for Cooperative Multi-Arm Robotic Systems with Third-Order Constraints. In 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems, IROS 2024 (pp. 3043-3048). IEEE/RSJ International Conference on Intelligent Robots and Systems, pp. 3043-3048. [DOI].

- Dio M, Graichen K, Völz A (2024). Time-Optimal Path Parameterization for Cooperative Multi-Arm Robotic Systems with Third-Order Constraints. In 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 3043-3048).

- Dio M, Völz A, Graichen K (2023). Cooperative dual-arm control for heavy object manipulation based on hierarchical quadratic programming. In 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 643-648).

- Dio M, Wahrburg A, Enayati N, Graichen K, Völz A (2025). Time-Optimal Path Parameterization with Viscous Friction and Jerk Constraints based on Reachability Analysis. In 2025 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS).

- Gold T, Völz A, Graichen K (2023). Model predictive interaction control for robotic manipulation tasks. IEEE Transactions on Robotics, 39(1), 76-89. [DOI].

- Goppelt-Schneider F, Schmidt-Vollus R, Graichen K (2024). Trajectory tracking control for multilevel pressure boosting systems. In 28th International Conference on System Theory, Control and Computing (ICSTCC).

- Harder K, Niemeyer J, Remele J, Graichen K (2023). Hierarchical model predictive control for an off-highway Diesel engine with SCR catalyst. International Journal of Engine Research. [DOI].

- Hartmann P, Graichen K (2025). Learning-based uncertainty-aware predictive control of truck-trailer systems in rough terrain. In 19th IEEE International Conference on Control & Automation (ICCA).

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2024). Fault detection in gauge-sensorized strain wave gears. In European Control Conference (pp. 26-33). [DOI].

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2023). Simulation chain for sensorized strain wave gears. In 27th International Conference on System Theory, Control and Computing (ICSTCC) (pp. 467 – 473). [DOI].

- Kowalewski J, Lorenz A, Thomas F, Valenzuela RAA, Graichen K (2025). Passivity-Based Robust Stability Analysis of the Converter–Grid Interaction and Passivity-Shaping Controller Design. IET Generation Transmission & Distribution, 19(1). [DOI].

- Kruse T, Griebel T, Graichen K (2025). Adaptive Kalman filtering: Measurement and process noise covariance estimation using Kalman smoothing. IEEE Access, 13, 11863-11875. [DOI].

- Landgraf D, Völz A, Berkel F, Schmidt K, Specker T, Graichen K (2023). Probabilistic prediction methods for nonlinear systems with application to stochastic model predictive control. Annual Reviews in Control, 56, 100905. [DOI].

- Landgraf D, Völz A, Graichen K (2025). A software framework for stochastic model predictive control of nonlinear continuous-time systems (GRAMPC-S). Optimization and Engineering. [DOI].

- Landgraf D, Wietzke T, Graichen K (2025). Stochastic model predictive control with switched latent force models. In European Control Conference (pp. 101311). European Journal of Control, 85, 101311. [DOI].

- Lukassek M, Dahlmann J, Völz A, Graichen K (2024). Model predictive path-following control for truck–trailer systems with specific guidance points – Design and experimental validation. Mechatronics, 100, 103190. [DOI].

- Löhe K, Reinhard J, Petrasch N, Kallabis S, Graichen K, Mucha M (2024). Work Roll Speed Drop Compensation for Hot Strip Mills Reduces Drivetrain Wear and Increases Strip Quality. In AISTech 2024 Iron and Steel Technology Conference (pp. 1212-1223). Warrendale, PA. [DOI].

- Pierer von Esch M, Landgraf D, Steffel M, Völz A, Graichen K (2024). Distributed stochastic optimal control of nonlinear systems based on ADMM. In 63th IEEE Conference on Decision and Control (CDC 2024).

- Pierer von Esch M, Landgraf D, Steffel M, Völz A, Graichen K (2024). Distributed Stochastic Optimal Control of Nonlinear Systems based on ADMM. IEEE Control Systems Letters, 8, 424-429. [DOI].

- Pierer von Esch M, Nistler E, Völz A, Graichen K (2025). Sensitivity-based distributed NMPC: Experimental results for a levitating planar motion system. IEEE Transactions on Control Systems Technology. [DOI].

- Pierer von Esch M, Völz A, Graichen K (2024). Sensitivity-Based Distributed Model Predictive Control: Synchronous and Asynchronous Execution Compared to ADMM. At-Automatisierungstechnik, 72(2), 91-106. [DOI].

- Pierer von Esch M, Völz A, Graichen K (2025). A fixed-point iteration scheme for sensitivity-based distributed optimal control. IEEE Transactions on Automatic Control, 70(4), 2778-2785. [DOI].

- Pierer von Esch M, Völz A, Graichen K (2024). Asynchronous ADMM for Nonlinear Continuous-Time Systems. Optimal Control Applications & Methods.

- Pierer von Esch M, Völz A, Graichen K (2025). Asynchronous sensitivity-based distributed optimal control for nonlinear systems. In 2025 American Control Conference (ACC).

- Pierer von Esch M, Völz A, Graichen K (2025). Sensitivity-Based Distributed Model Predictive Control for Nonlinear Systems under Inexact Optimization. Optimal Control Applications & Methods, (accepted).

- Pierer von Esch M, Völz A, Graichen K (2024). Sensitivity-based distributed model predictive control: synchronous and asynchronous execution compared to ADMM. At-Automatisierungstechnik, 72(2), 91-106. [DOI].

- Reinhard J, Löhe K, Graichen K (2024). Optimal dynamic current control for externally excited synchronous machines. In 2024 IEEE Conference on Control Technology and Applications (CCTA) (pp. 146-152). [DOI].

- Reinhard J, Löhe K, Petrasch N, Kallabis S, Graichen K (2024). Dynamic compensation of the threading speed drop in rolling processes. Journal of Process Control, 137, 103197. [DOI].

- Spenger P, Graichen K (2023). Performance prediction of NMPC algorithms with incomplete optimization. In 22nd IFAC World Congress (pp. 7456-7461).

- Südhoff T, Ebner L, Schmidt J, Graichen K (2024). GP-based modeling for PSD control of emulsification processes. In 28th International Conference on System Theory, Control and Computing (ICSTCC).

- Burk D, Völz A, Graichen K (2022). A modular framework for distributed model predictive control of nonlinear continuous-time systems (GRAMPC-D). Optimization and Engineering, 23, 771-795. [DOI].

- Burk D, Völz A, Graichen K (2022). Improving the performance of distributed model predictive control by applying graph partitioning methods. In 26th International Conference on System Theory, Control and Computing (ICSTCC). [DOI].

- Dahlmann J, Volz A, Szabo T, Graichen K (2022). A Numerical Approach for Solving the Inversion Problem for n-Trailer Systems. In 2022 American Control Conference, ACC 2022 (pp. 2018-2024). Proceedings of the American Control Conference, 2022-June, 2018-2024. [DOI].

- Dahlmann J, Völz A, Szabo T, Graichen K (2022). A numerical approach for solving the inversion problem for general n-trailer systems.. In Proceedings 2022 American Control Conference (ACC) (pp. 2018-2024). [DOI].

- Dahlmann J, Völz A, Szabo T, Graichen K (2022). Trajectory optimization for truck-trailer systems based on predictive path-following control. In 6th IEEE Conference on Control Technology and Applications (CCTA). [DOI].

- Gold T, Römer R, Völz A, Graichen K (2022). Catching objects with a robot arm using model predictive control. In Proceedings 2022 American Control Conference (ACC) (pp. 1915-1920). [DOI].

- Huber H, Burk D, Graichen K (2022). Comparison of sensitivity-based and ADMM-based DMPC applied to building automation. In 6th IEEE Conference on Control Technology and Applications (CCTA) (pp. 546-553). [DOI].

- Kowalewski J, Lorenz A, Lomakin A, Alvarez R, Graichen K (2022). Circulating current control and energy balancing of a modular multilevel converter using model predictive control for HVDC applications. In 48th Annual Conference of the IEEE Industrial Electronics Society (IECON 2022). [DOI].

- Lamprecht A, Steffen D, Nagel K, Häcker J, Graichen K (2022). Online Model Predictive Motion Cueing With Real-Time Driver Prediction. IEEE Transactions on Intelligent Transportation Systems, 23(8), 12414-12428. [DOI].

- Landgraf D, Völz A, Graichen K (2022). Nonlinear model predictive control with latent force models. In Proceedings 2022 American Control Conference (ACC) (pp. 4979-4984). [DOI].

- Landgraf D, Völz A, Kontes G, Graichen K, Mutschler C (2022). Hierarchical learning for model predictive collision avoidance. In 10th Vienna International Conference on Mathematical Modelling (MATHMOD 22) (pp. 355-360). [DOI].

- Reinhard J, Löhe K, Graichen K (2022). Optimal current setpoint computation for externally excited synchronous machines. In 6th IEEE Conference on Control Technology and Applications (CCTA) (pp. 1319-1326). [DOI].

- Snobar F, Reinhard J, Huber H, Hoffmann M, Stelzig M, Vossiek M, Graichen K (2022). FOV-based model predictive object tracking for quadcopters. In 9th IFAC Symposium on Mechatronic Systems (Mechatronics 2022) (pp. 13 – 18). [DOI].

- Stecher J, Kiltz L, Graichen K (2022). Semi-infinite programming using Gaussian process regression for robust design optimization. In Proceedings European Control Conference (pp. 52-59). [DOI].

- Burk D, Völz A, Graichen K (2021). Experimental validation of the open-source DMPC framework GRAMPC-D applied to the remote-accessible robotarium. In IEEE International Conference on Mechatronics and Automation (ICMA). [DOI].

- Burk D, Völz A, Graichen K (2021). Towards asynchronous ADMM for distributed model predictive control of nonlinear systems. In Proceedings European Control Conference (ECC 2021) (pp. 1950-1955). [DOI].

- Gold T, Rohrmüller M, Völz A, Graichen K (2021). Model predictive interaction control for force closure grasping. In 2021 IEEE Conference on Decision and Control (CDC) (pp. 1018-1023). [DOI].

- Huber H, Graichen K (2021). A sensitivity-based distributed model predictive control algorithm for nonlinear continuous-time systems. In 5th IEEE Conference on Control Technology and Applications (CCTA) (pp. (accepted)). [DOI].

- Lamprecht A, Emmert T, Graichen K (2021). Learning-based driver prediction for MPC-based motion cueing algorithms. In Driving Simulation Conference Europe 2021 (DSC) (pp. 133 – 140).

- Lamprecht A, Steffen D, Häcker J, Graichen K (2021). Potential der modellprädiktiven Regelung für Fahrsimulatoren. At-Automatisierungstechnik, 69(2), 155-170. [DOI].

- Lukassek M, Völz A, Szabo T, Graichen K (2021). Model predictive path-following control for general n-trailer systems with an arbitrary guidance point. In Proceedings European Control Conference (ECC 2021) (pp. 1329-1334). [DOI].

- Völz A, Graichen K (2021). Gradient-based nonlinear model predictive control for systems with state-dependent mass matrix. In 2021 IEEE Conference on Decision and Control (CDC), accepted. [DOI].

- Burk D, Völz A, Graichen K (2020). Distributed optimization with ALADIN for non-convex optimal control problems. In 59th IEEE Conference on Decision and Control (CDC 2020). [DOI].

- Burk D, Völz A, Graichen K (2020). Neighbor approximations for distributed optimal control of nonlinear networked systems. In European Control Conference (ECC 2020) (pp. 1238-1243). [DOI].

- Englert T, Graichen K (2020). Nonlinear model predictive torque control and setpoint computation of induction machines for high performance applications. Control Engineering Practice, 99. [DOI].

- Gold T, Lomakin A, Goller T, Völz A, Graichen K (2020). Towards a Generic Manipulation Framework for Robots based on Model Predictive Interaction Control. In IEEE International Conference on Mechatronics and Automation (ICMA) (pp. 401 – 407). [DOI].

- Gold T, Völz A, Graichen K (2020). Model Predictive Interaction Control for Industrial Robots. In 21st IFAC World Congress (pp. 10026 – 10033). [DOI].

- Gold T, Völz A, Graichen K (2020). Model Predictive Position and Force Trajectory Tracking Control for Robot-Environment Interaction. In 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 7397-7402). [DOI].

- Kruse T, Graichen K (2020). Moving horizon estimation for continuous glucose monitoring. In 7th International Conference on Biomedical Engineering and Systems (ICBES 20). [DOI].

- Lomakin A, Mayr A, Graichen K, Franke J (2020). Optimization of direct winding processes based on a holistic control approach. In Electric Drives Production Conference (E-DPC). [DOI].

- Lukassek M, Völz A, Szabo T, Graichen K (2020). Model predictive control for agricultural machines with implements. In Proceedings 28th Mediterranean Conference on Control and Automation (MED) (pp. 387-392). [DOI].

- Bestler A, Graichen K (2019). Distributed model predictive control for continuous-time nonlinear systems based on suboptimal ADMM. Optimal Control Applications & Methods, 40(1), 1-23. [DOI].

- Burk D, Völz A, Graichen K (2019). Towards a modular framework for distributed model predictive control of nonlinear neighbor-affine systems. In 58th IEEE Conference on Decision and Control (CDC 2019) (pp. 5279-5284). [DOI].

- Englert T, Völz A, Mesmer F, Rhein S, Graichen K (2019). A software framework for embedded nonlinear model predictive control using a gradient-based augmented Lagrangian approach (GRAMPC). Optimization and Engineering, 20(3), 769-809. [DOI].

- Gold T, Völz A, Graichen K (2019). External torque estimation for an industrial robot arm using joint torsion and motor current measurements. In Joint Conference 8th IFAC Symposium on Mechatronic Systems (MECHATRONICS) and 11th IFAC Symposium on Nonlinear Control Systems (NOLCOS) (pp. 879-884). Vienna (Austria). [DOI].

- Lamprecht A, Steffen D, Häcker J, Graichen K (2019). Comparison between a Filter- and an MPC-based MCA in an Offline Simulator Study. In Driving Simulation Conference & Exhibition (DSC) (pp. 101-107).

- Lamprecht A, Steffen D, Häcker J, Graichen K (2019). Optimal control based reference generation for model predictive motion cueing algorithms. In 3rd IEEE Conference on Control Technology and Application (CCTA 2019) (pp. 203-208). Hong Kong (China). [DOI].

- Englert T, Graichen K (2018). A fixed-point iteration scheme for model predictive torque control of PMSMs. In Proceedings 6th IFAC Conference on Nonlinear Model Predictive Control (NMPC) (pp. 668-673). Madison, WI (USA).

- Graichen K, Hentzelt S (2015). A bi-level nonlinear predictive control scheme for hopping robots with hip and tail actuation. In Proceedings 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2015) (pp. 4480-4485). Hamburg (Germany).

- Graichen K, Käpernick B (2012). A real-time gradient method for nonlinear model predictive control. In Zheng T (Eds.), Frontiers of Model Predictive Control, pp. 9-28. [DOI].

- Graichen K, Käpernick B (2012). Nonlinear MPC with systematic handling of a class of constraints. In Oberwolfach Report No. 12/2012 (Workshop “Control Theory: Mathematical Perspectives on Complex Networked Systems”) (pp. 17-18). Oberwolfach (Germany). [DOI].

- Harder K, Buchholz M, Späder T, Graichen K (2018). A real-time nonlinear air path observer for off-highway diesel engines. In Proceedings 2018 European Control Conference (ECC) (pp. 237-242). Limassol (Cyprus).

- Hentzelt S, Graichen K (2013). An augmented Lagrangian method in distributed dynamic optimization based on approximate neighbor dynamics. In Proceedings IEEE Intern. Conf. Systems, Man, and Cybernetics (SMC 2013) (pp. 571-576). Manchester (UK).

- Hentzelt S, Graichen K (2012). Dual decomposition of optimal control problems with coupled nonlinear dynamics. In CD-ROM Proceedings European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2012). Vienna (Austria).

- Hentzelt S, Graichen K (2014). Experimental results for distributed model predictive control applied to a water distribution system. In Proceedings 2014 IEEE Multi-Conference on Systems and Control (pp. 1100-1106). Nice (France).

- Kaepernick B, Graichen K (2014). PLC implementation of a nonlinear model predictive controller. In Proceedings 19th IFAC World Congress (pp. 1892-1897). Cape Town (South Africa).

- Käpernick B, Graichen K (2013). Transformation of output constraints in optimal control applied to a double pendulum on a cart. In Proceedings 9th IFAC Symposium “Nonlinear Control Systems” (NOLCOS) (pp. 193-198). Toulouse (Italy).

- Käpernick B, Graichen K (2013). Model predictive control of an overhead crane using constraint substitution. In Proceedings 2013 American Control Conference (ACC) (pp. 3979-3984). Washington, DC (USA).

- Käpernick B, Graichen K (2014). Nichtlineare modellprädiktive Regelung auf SPS. Automatisierungstechnische Praxis, 56, 38-46. [DOI].

- Käpernick B, Graichen K (2014). The gradient based nonlinear model predictive control software GRAMPC. In Proceedings 13th European Control Conference (ECC) (pp. 1170-1175). Strasbourg (France).

- Käpernick B, Hentzelt S, Graichen K (2013). A parallelizable decomposition approach for constrained optimal control problems. In Proceedings 52th IEEE Conference on Decision and Control (CDC) (pp. 5783-5788). Florence (Italy).

- Käpernick B, Süß S, Schubert E, Graichen K (2014). A synthesis strategy for nonlinear model predictive controller on FPGA. In Proceedings 2014 UKACC 10th International Conference on Control (pp. 662-667). Loughborough (UK).

- Lamprecht A, Häcker J, Graichen K (2018). Constrained motion cueing for driving simulators using a real-time nonlinear MPC scheme. In Proceedings 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (pp. 7466-7471). Madrid (Spain).

- Rhein S, Graichen K (2018). Constrained trajectory planning and actuator design for electromagnetic heating systems. Control Engineering Practice, 74, 191-203.

- Rhein S, Utz T, Graichen K (2014). Efficient state constraint handling for MPC of the heat equation. In Proceedings 2014 UKACC 10th International Conference on Control (pp. 663-668). Loughborough (UK).

- Rhein S, Utz T, Graichen K (2013). Model predictive control and moving horizon estimation of a large-scale chemical reactor model. In Proceedings 1st {IFAC} Symposium on Control of Systems Governed by Partial Differential Equations (CPDE) (pp. 121-126). Paris (France).

- Utz T, Rhein S, Graichen K (2014). Transformation approach to constraint handling in optimal control of the heat equation. In Proceedings 19th IFAC World Congress (pp. 9135-9140). Cape Town (South Africa).

Mechatronics & Automotive

Mechatronic systems consist of both mechanical and electrical components. Typical challenges are the high integration of these systems along with the limited computational resources of embedded hardware such as electronic control units (ECUs) in automotive applications. We have a successful history of bridging the gap between theory and practice in close cooperation with industrial partners from the mechatronics and automotive domain.

Contact

Prof. Dr.-Ing. Knut Graichen

Tel.: +49 9131 85-27127

E-Mail | Homepage

Dr.-Ing. Andreas Michalka

Tel.: +49 9131 85-28592

E-Mail | Homepage

Highly integrated mechatronic systems can, for instance, be found in electric drives, power trains, and sensors. Future mechatronic applications will not only involve classical control loops, but will also be equipped with further intelligent and autonomous functionalities such as automatic calibration, fault-tolerant operation and predictive maintenance.

Automotive-related applications such as passenger cars, trucks or agricultural machines involve a multitude of control systems. This ranges from active suspension, traction control, assisted driving up to fully autonomous driving. On the lower level, efficient embedded control implementations are predominant, whereas higher level control loops involve complex decision making in combination with environmental perception.

State-of-the-art modeling approaches of mechatronic systems combine physics-based and data-driven design methods to account for the uncertainties introduced, for example, by wear, aging and serial production spread. A particular expertise of the Chair is to leverage these hybrid models for sophisticated control schemes and the development of tailored algorithms for real-time capable implementations.

Videos

Related projects since 2021

Funding source: Bayerische Forschungsstiftung

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Bundesministerium für Forschung, Technologie und Raumfahrt (BMFTR)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Related publications

- Dahlmann J, Graichen K, Völz A (2024). Ein Konzept zum automatisierten Rangieren von Fahrzeugen mit Anhängern. At-Automatisierungstechnik, 72(4), 354-368. [DOI].

- Dahlmann J, Völz A, Lukassek M, Graichen K (2024). Local predictive optimization of globally planned motions for truck-trailer systems. IEEE Transactions on Control Systems Technology, 32(5), 1555-1568. [DOI].

- Dio M, Demir O, Trachte A, Graichen K (2023). Safe active learning and probabilistic design of experiment for autonomous hydraulic excavators. In 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 9685-9690).

- Goppelt-Schneider F, Schmidt-Vollus R, Graichen K (2024). Trajectory tracking control for multilevel pressure boosting systems. In 28th International Conference on System Theory, Control and Computing (ICSTCC).

- Harder K, Niemeyer J, Remele J, Graichen K (2023). Hierarchical model predictive control for an off-highway Diesel engine with SCR catalyst. International Journal of Engine Research. [DOI].

- Hartmann P, Graichen K (2025). Learning-based uncertainty-aware predictive control of truck-trailer systems in rough terrain. In 19th IEEE International Conference on Control & Automation (ICCA).

- Lukassek M, Dahlmann J, Völz A, Graichen K (2024). Model predictive path-following control for truck–trailer systems with specific guidance points – Design and experimental validation. Mechatronics, 100, 103190. [DOI].

- Löhe K, Reinhard J, Petrasch N, Kallabis S, Graichen K, Mucha M (2024). Work Roll Speed Drop Compensation for Hot Strip Mills Reduces Drivetrain Wear and Increases Strip Quality. In AISTech 2024 Iron and Steel Technology Conference (pp. 1212-1223). Warrendale, PA. [DOI].

- Rabenstein G, Ullrich L, Graichen K (2024). Sampling for model predictive trajectory planning in autonomous driving using normalizing flows. In 35th IEEE Intelligent Vehicles Symposium (IEEE IV 2024) (pp. 2091-2096).

- Reinhard J, Löhe K, Graichen K (2024). Optimal dynamic current control for externally excited synchronous machines. In 2024 IEEE Conference on Control Technology and Applications (CCTA) (pp. 146-152). [DOI].

- Reinhard J, Löhe K, Petrasch N, Kallabis S, Graichen K (2024). Dynamic compensation of the threading speed drop in rolling processes. Journal of Process Control, 137, 103197. [DOI].

- Santer P, Reinhard J, Schindler A, Graichen K (2025). Detection of localized bearing faults in PMSMs by means of envelope analysis and wavelet packet transform using motor speed and current signals. Mechatronics, 106. [DOI].

- Schumann M, Ebersberger S, Graichen K (2023). Online learning and adaptation of nonlinear thermal networks for power inverters. In 49th Annual Conference of the IEEE Industrial Electronics Society (IECON 2023).

- Schumann M, Ebersberger S, Graichen K (2023). Improved nonlinear estimation in thermal networks using machine learning. In IEEE International Conference on Mechatronics (ICM 2023). [DOI].

- Schumann M, Graichen K (2024). PINN-based dynamical modeling and state estimation in power inverters. In 2024 IEEE Conference on Control Technology and Applications (CCTA).

- Snobar F, Michalka A, Horn M, Strohmeyer C, Graichen K (2023). Rack force estimation from standstill to high speeds by hybrid model design and blending. In IEEE International Conference on Mechatronics (ICM 2023). [DOI].

- Snobar F, Michalka A, Horn M, Strohmeyer C, Graichen K (2024). Sensitivity-based moving horizon estimation of road friction. In European Control Conference (pp. 718-724).

- Ullrich L, Buchholz M, Dietmayer K, Graichen K (2024). AI safety assurance for automated vehicles: A survey on research, standardization, regulation. IEEE Transactions on Intelligent Vehicles. [DOI].

- Ullrich L, Buchholz M, Dietmayer K, Graichen K (2024). Expanding the Classical V-Model for the Development of Complex Systems Incorporating AI. IEEE Transactions on Intelligent Vehicles. [DOI].

- Ullrich L, Buchholz M, Petit J, Dietmayer K, Graichen K (2025). A Concept for Efficient Scalability of Automated Driving Allowing for Technical, Legal, Cultural, and Ethical Differences. In 2025 IEEE 28th International Conference on Intelligent Transportation Systems (ITSC).

- Ullrich L, McMaster A, Graichen K (2024). Transfer learning study of motion transformer based trajectory predictions. In 35th IEEE Intelligent Vehicles Symposium (IEEE IV 2024) (pp. 110-117).

- Ullrich L, Mujirishvili Z, Graichen K (2025). Enhancing system self-awareness and trust of AI: A case study in trajectory prediction and planning. In 36th IEEE Intelligent Vehicles Symposium (IEEE IV 2025).

- Ullrich L, Völz A, Graichen K (2023). Robust meta-learning of vehicle yaw rate dynamics via conditional neural processes. In 62nd IEEE Conference on Decision and Control (CDC) (pp. 322-327).

- Ullrich L, Zimmer W, Greer R, Graichen K, Knoll AC, Trivedi M (2025). A New Perspective On AI Safety Through Control Theory Methodologies. IEEE Open Journal of Intelligent Transportation Systems, 6, 938-966. [DOI].

- Bergmann D, Harder K, Niemeyer J, Graichen K (2022). Nonlinear MPC of a Heavy-Duty Diesel Engine With Learning Gaussian Process Regression. IEEE Transactions on Control Systems Technology, 30(1), 113-129. [DOI].

- Dahlmann J, Volz A, Szabo T, Graichen K (2022). A Numerical Approach for Solving the Inversion Problem for n-Trailer Systems. In 2022 American Control Conference, ACC 2022 (pp. 2018-2024). Proceedings of the American Control Conference, 2022-June, 2018-2024. [DOI].

- Dahlmann J, Völz A, Szabo T, Graichen K (2022). A numerical approach for solving the inversion problem for general n-trailer systems.. In Proceedings 2022 American Control Conference (ACC) (pp. 2018-2024). [DOI].

- Dahlmann J, Völz A, Szabo T, Graichen K (2022). Trajectory optimization for truck-trailer systems based on predictive path-following control. In 6th IEEE Conference on Control Technology and Applications (CCTA). [DOI].

- Rabenstein G, Demir O, Trachte A, Graichen K (2022). Data-driven feed-forward control of hydraulic cylinders using Gaussian process regression for excavator assistance functions. In 6th IEEE Conference on Control Technology and Applications (CCTA) (pp. 962-969). [DOI].

- Reinhard J, Löhe K, Graichen K (2022). Optimal current setpoint computation for externally excited synchronous machines. In 6th IEEE Conference on Control Technology and Applications (CCTA) (pp. 1319-1326). [DOI].

- Schumann M, Ebersberger S, Graichen K (2022). Dynamic and stationary state estimation of fluid cooled three-phase inverters. In 26th IEEE International Symposium on Power Electronics, Electrical Drives Automation and Motion (SPEEDAM 2022). [DOI].

- Lukassek M, Völz A, Szabo T, Graichen K (2021). Model predictive path-following control for general n-trailer systems with an arbitrary guidance point. In Proceedings European Control Conference (ECC 2021) (pp. 1329-1334). [DOI].

- Bergmann D, Graichen K (2020). Safe Bayesian Optimization under Unknown Constraints. In 59th IEEE Conference on Decision and Control, CDC 2020 (pp. 3592-3597). [DOI].

- Englert T, Graichen K (2020). Nonlinear model predictive torque control and setpoint computation of induction machines for high performance applications. Control Engineering Practice, 99. [DOI].

- Geiselhart R, Bergmann D, Niemeyer J, Remele J, Graichen K (2020). Hierarchical Predictive Control of a Combined Engine/Selective Catalytic Reduction System with Limited Model Knowledge. SAE International Journal of Engines, 13(2). [DOI].

- Geiselhart R, Bergmann D, Niemeyer J, Remele J, Graichen K (2020). Hierarchical predictive control of a combined engine/SCR system with limited model knowledge. SAE International Journal of Engines, 13(2). [DOI].

- Lukassek M, Völz A, Szabo T, Graichen K (2020). Model predictive control for agricultural machines with implements. In Proceedings 28th Mediterranean Conference on Control and Automation (MED) (pp. 387-392). [DOI].

- Mesmer F, Szabo T, Graichen K (2020). Learning feedforward control of a hydraulic clutch actuation path based on policy gradients. In 59th IEEE Conference on Decision and Control (CDC 2020). [DOI].

- Bergmann D, Geiselhart R, Graichen K (2019). Modelling and control of a heavy-duty Diesel engine gas path with Gaussian process regression. In Proc. European Control Conference (ECC 2019) (pp. 1207-1213). Naples (Italy). [DOI].

- Bergmann D, Graichen K (2019). Gaußprozessregression zur Modellierung zeitvarianter Systeme. At-Automatisierungstechnik, 67(8), 637-647. [DOI].

- Mesmer F, Szabo T, Graichen K (2019). Learning methods for the feedforward control of a hydraulic clutch actuation path. In Proc. IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM 2019) (pp. 733-738). Hong Kong (China). [DOI].

- Mesmer F, Szabo T, Graichen K (2019). Feedforward control of a hydraulic clutch actuation path. In Proc. European Control Conference (ECC 2019) (pp. 620-626). Naples (Italy). [DOI].

- Englert T, Graichen K (2018). A fixed-point iteration scheme for model predictive torque control of PMSMs. In Proceedings 6th IFAC Conference on Nonlinear Model Predictive Control (NMPC) (pp. 668-673). Madison, WI (USA).

- Harder K, Buchholz M, Späder T, Graichen K (2018). A real-time nonlinear air path observer for off-highway diesel engines. In Proceedings 2018 European Control Conference (ECC) (pp. 237-242). Limassol (Cyprus).

- Käpernick B, Graichen K (2013). Model predictive control of an overhead crane using constraint substitution. In Proceedings 2013 American Control Conference (ACC) (pp. 3979-3984). Washington, DC (USA).

- Käpernick B, Graichen K (2013). Transformation of output constraints in optimal control applied to a double pendulum on a cart. In Proceedings 9th IFAC Symposium “Nonlinear Control Systems” (NOLCOS) (pp. 193-198). Toulouse (Italy).

Robotics

Robotics deals in general with machines that can assist in or perform the execution of tasks such as assembly or machining by industrial robots. Research projects in this area concern, for example, the control of motions and forces in human-robot interaction as well as the planning of paths and trajectories for mobile and collaborative robots.

Contact

Dr.-Ing. Andreas Völz

Tel.: +49 9131 85-61036

E-Mail | Homepage

Prof. Dr.-Ing. Knut Graichen

Tel.: +49 9131 85-27127

E-Mail | Homepage

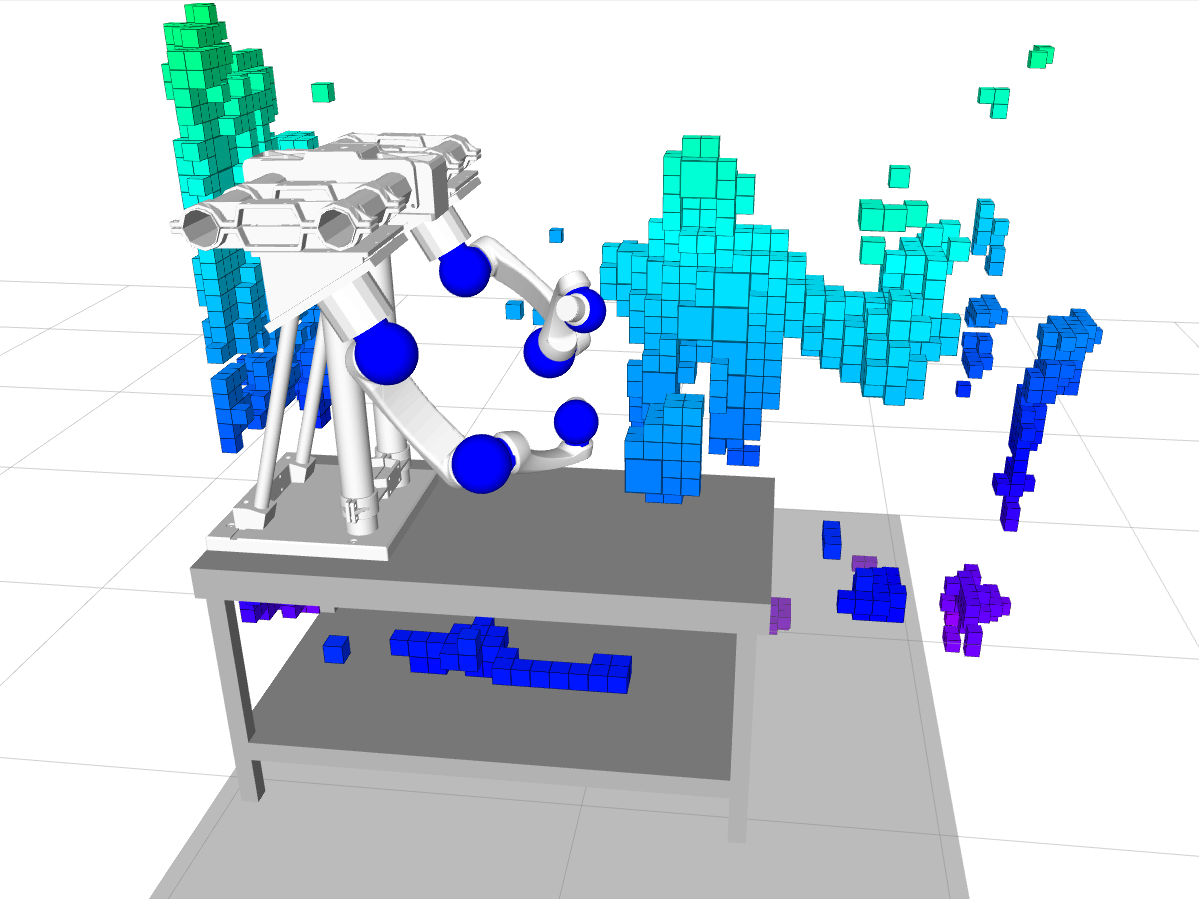

Robots should move and interact with humans as efficiently as possible. If this includes high velocities or heavy payloads, the nonlinear rigid body dynamics as well as the input constraints need to be taken into account, which leads to a computationally demanding optimization problem. On the other hand, when the robot is in contact with its environment, the rigid body dynamics are often less relevant, but the forces and torques that arise must be considered by the control system. This is especially important for safe human-robot interaction. Here, the challenges include the contact modelling (e.g. stiffness and friction), the safe handling of contact loss, or the selection of controller parameters for different applications. Current research considers model predictive interaction control (MPIC), which refers to MPC with explicit prediction of contact forces and torques, as well as the development of specialized algorithms for solving optimization problems with rigid body dynamics.

Besides controlling motions, also the planning of paths (geometric description) and trajectories (time information) is a relevant problem for many types of robots. In particular for mobile and collaborative robots, motions should be planned in such a way that they do not cause self-collisions or collisions with obstacles in the environment. Global planners iteratively build a search structure that explores the space of possible motions, whereas local planners only search in the neighborhood of an initial solution. In order to efficiently find high-quality solutions, it is necessary to combine the advantages of both global and local planning methods. Further difficulties arise in dynamic environments, where the future motion of obstacles needs to be predicted or for car-like robots, where the non-holonomic kinematics need to be considered.

The Chair is equipped with a mobile dual-arm robot as well as a motion capturing system that have been funded by the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG) through the major instrumentation proposal INST 90/1167-1 FUGG. The system enables the experimental validation of planning and control methods for mobile manipulation in workspaces shared with humans. For more information contact Prof. Dr.-Ing. Knut Graichen or Dr.-Ing. Andreas Völz.

Videos

- Writing on a blackboard with chalk – MPIC hybrid force/motion control (IEEE IROS 2020: DOI: 10.1109/IROS45743.2020.9341168)

- Anthropomorphic in-hand manipulation – MPIC for force closure grasping (IEEE CDC 2021)

- Catching objects in flight – MPIC for time-optimal trajectory planning

- Admittance control of the XPlanar system for human-mover interaction

- Collision-free motion planning for a rotating robot with seven degrees of freedom

- Collision-free motion planning for a dual-arm robot with twelve degrees of freedom

- Motion planning for a dual-arm robot with closed kinematics

- Predictive path-following control for continuous replanning with dynamic roadmaps (IEEE RA-L 2019, DOI: 1109/LRA.2019.2929990)

Related projects since 2021

Funding source: Deutsche Forschungsgemeinschaft (DFG)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Precise interactions as part of industrial manufacturing tasks are typically very complex to characterize and implement. One reason for this is the heterogeneity of the task-specific requirements for the motion and control behavior. A direct implementation of the task into a robot program therefore requires highly qualified specialists and is only profitable for large lot sizes. For a flexible applicability and easy (re-)configuration of the robot system, an approach to programming by kinesthetic…

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: DFG-Einzelförderung / Sachbeihilfe (EIN-SBH)

Project leader:

Dr.-Ing. Andreas Völz

Senior Lecturer

Dual-armrobots offer a high potential for automation technology, as they canbe used to implement tasks that are not possible with one arm alone.This includes in particular the manipulation of large or heavyobjects that exceed the payload of a single arm. Illustrativeexamples are the movement of beverage crates, long boards or pipes,which are also preferably grasped by humans with both hands.

However,cooperative manipulation is particularly challenging, because botharms and the grasped object…

Funding source: Bundesministerium für Wirtschaft und Energie (BMWE)

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Funding source: Industrie

Project leader:

Prof. Dr.-Ing. Knut Graichen

Chair holder

Related publications

- Dio M, Graichen K, Völz A (2024). Time-Optimal Path Parameterization for Cooperative Multi-Arm Robotic Systems with Third-Order Constraints. In 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems, IROS 2024 (pp. 3043-3048). IEEE/RSJ International Conference on Intelligent Robots and Systems, pp. 3043-3048. [DOI].

- Dio M, Graichen K, Völz A (2024). Time-Optimal Path Parameterization for Cooperative Multi-Arm Robotic Systems with Third-Order Constraints. In 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 3043-3048).

- Dio M, Völz A, Graichen K (2023). Cooperative dual-arm control for heavy object manipulation based on hierarchical quadratic programming. In 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 643-648).

- Dio M, Wahrburg A, Enayati N, Graichen K, Völz A (2025). Time-Optimal Path Parameterization with Viscous Friction and Jerk Constraints based on Reachability Analysis. In 2025 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS).

- Gold T, Völz A, Graichen K (2023). Model predictive interaction control for robotic manipulation tasks. IEEE Transactions on Robotics, 39(1), 76-89. [DOI].

- Goller T, Brohm D, Völz A, Graichen K (2024). DMP-based path planning for model predictive interaction control. In European Control Conference (pp. 128-133).

- Goller T, Hopf V, Völz A, Graichen K (2025). Fault Handling in Robotic Manipulation Tasks for Model Predictive Interaction Control. IEEE Robotics and Automation Letters, 10(9), 9002 – 9009. [DOI].

- Goller T, Völz A, Graichen K (2024). A Programming by Demonstration Approach for Robotic Manipulation with Model Predictive Interaction Control. In 2024 IEEE Conference on Control Technology and Applications (CCTA) (pp. 799-804).

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2025). Estimation of input rotation speed in gauge-sensorized strain wave gears. In 2025 IEEE Conference on Control Technology and Applications (CCTA).

- Kißkalt J, Michalka A, Strohmeyer C, Horn M, Graichen K (2025). Model-based fault simulation and detection for gauge-sensorized strain wave gears. In 11th Vienna International Conference on Mathematical Modelling (MATHMOD 25) (pp. 271 – 276). [DOI].

- Rabenstein G, Völz A, Graichen K (2025). Cable Manipulation for Contact Shaping Tasks using Elastic Rods. In IEEE International Conference on Advanced Robotics and Mechatronics (ICARM).

- Rohrmüller M, Beckerle P, Graichen K, Malvezzi M, Pozzi M (2023). In-Hand Manipulation with Synergistic Actuated Robotic Hands: An MPC-Based Approach. In 22nd IEEE-RAS International Conference on Humanoid Robots, Humanoids 2023. [DOI].

- Santer P, Völz A, Graichen K (2025). A Model Predictive Control Approach to Trajectory Tracking with Human-Robot Collision Avoidance. In 2025 IEEE Conference on Control Technology and Applications (CCTA).

- Gold T, Römer R, Völz A, Graichen K (2022). Catching objects with a robot arm using model predictive control. In Proceedings 2022 American Control Conference (ACC) (pp. 1915-1920). [DOI].

- Goller T, Gold T, Völz A, Graichen K (2022). Model predictive interaction control based on a path-following formulation. In Proceedings IEEE International Conference on Mechatronics and Automation (ICMA) (pp. 551-556). [DOI].

- Lamprecht A, Steffen D, Nagel K, Häcker J, Graichen K (2022). Online Model Predictive Motion Cueing With Real-Time Driver Prediction. IEEE Transactions on Intelligent Transportation Systems, 23(8), 12414-12428. [DOI].

- Snobar F, Reinhard J, Huber H, Hoffmann M, Stelzig M, Vossiek M, Graichen K (2022). FOV-based model predictive object tracking for quadcopters. In 9th IFAC Symposium on Mechatronic Systems (Mechatronics 2022) (pp. 13 – 18). [DOI].

- Burk D, Völz A, Graichen K (2021). Experimental validation of the open-source DMPC framework GRAMPC-D applied to the remote-accessible robotarium. In IEEE International Conference on Mechatronics and Automation (ICMA). [DOI].

- Gold T, Rohrmüller M, Völz A, Graichen K (2021). Model predictive interaction control for force closure grasping. In 2021 IEEE Conference on Decision and Control (CDC) (pp. 1018-1023). [DOI].

- Lamprecht A, Emmert T, Graichen K (2021). Learning-based driver prediction for MPC-based motion cueing algorithms. In Driving Simulation Conference Europe 2021 (DSC) (pp. 133 – 140).

- Lamprecht A, Steffen D, Häcker J, Graichen K (2021). Potential der modellprädiktiven Regelung für Fahrsimulatoren. At-Automatisierungstechnik, 69(2), 155-170. [DOI].

- Völz A, Graichen K (2021). Gradient-based nonlinear model predictive control for systems with state-dependent mass matrix. In 2021 IEEE Conference on Decision and Control (CDC), accepted. [DOI].

- Gold T, Lomakin A, Goller T, Völz A, Graichen K (2020). Towards a Generic Manipulation Framework for Robots based on Model Predictive Interaction Control. In IEEE International Conference on Mechatronics and Automation (ICMA) (pp. 401 – 407). [DOI].

- Gold T, Völz A, Graichen K (2020). Model Predictive Interaction Control for Industrial Robots. In 21st IFAC World Congress (pp. 10026 – 10033). [DOI].

- Gold T, Völz A, Graichen K (2020). Model Predictive Position and Force Trajectory Tracking Control for Robot-Environment Interaction. In 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (pp. 7397-7402). [DOI].

- Graichen K, Völz A (2020). Prädiktive Pfadfolgeregelung für die kollisionsfreie Bewegungsplanung von Robotern. At-Automatisierungstechnik, 68(7), 557-570. [DOI].

- Völz A, Graichen K (2020). Prädiktive Pfadfolgeregelung für die kollisionsfreie Bewegungsplanung von Robotern. At-Automatisierungstechnik, 68(7), 557-570. [DOI].

- Gold T, Völz A, Graichen K (2019). External torque estimation for an industrial robot arm using joint torsion and motor current measurements. In Joint Conference 8th IFAC Symposium on Mechatronic Systems (MECHATRONICS) and 11th IFAC Symposium on Nonlinear Control Systems (NOLCOS) (pp. 879-884). Vienna (Austria). [DOI].

- Lamprecht A, Steffen D, Häcker J, Graichen K (2019). Comparison between a Filter- and an MPC-based MCA in an Offline Simulator Study. In Driving Simulation Conference & Exhibition (DSC) (pp. 101-107).

- Lamprecht A, Steffen D, Häcker J, Graichen K (2019). Optimal control based reference generation for model predictive motion cueing algorithms. In 3rd IEEE Conference on Control Technology and Application (CCTA 2019) (pp. 203-208). Hong Kong (China). [DOI].

- Völz A, Graichen K (2019). A predictive path-following controller for continuous replanning with dynamic roadmaps. IEEE Robotics and Automation Letters, 4(4), 3963-3970. [DOI].

- Graichen K, Hentzelt S (2015). A bi-level nonlinear predictive control scheme for hopping robots with hip and tail actuation. In Proceedings 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2015) (pp. 4480-4485). Hamburg (Germany).

- Lamprecht A, Häcker J, Graichen K (2018). Constrained motion cueing for driving simulators using a real-time nonlinear MPC scheme. In Proceedings 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (pp. 7466-7471). Madrid (Spain).

- Völz A, Graichen K (2016). Distance metrics for path planning with dynamic roadmaps. In Proceedings 47th International Symposium on Robotics (ISR) (pp. 126-132). München (Germany).

- Völz A, Graichen K (2018). An optimization-based approach to dual-arm motion planning with closed kinematics. In Proceedings 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (pp. 8346-8351). Madrid (Spain).

- Völz A, Graichen K (2017). Composition of dynamic roadmaps for dual-arm motion planning. In Proceedings 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM 2017) (pp. 1242-1248). Munich (Germany).

- Völz A, Graichen K (2018). Computation of collision distance and gradient using an automatic sphere approximation of the robot model with bounded error. In Proceedings 50th International Symposium on Robotics (ISR) (pp. 322-329). München (Germany).

Publications

- Conrad, P., Michalka, A., Beck, J., & Graichen, K. (2025). Nonlinear MPC for Stabilizing the Longitudinal Dynamics of a Highly Maneuverable Aircraft. In Proc. 2025 IEEE Aerospace Conference. Big Sky, Montana (USA).

- Conrad, P., Steuter, L., Pierer von Esch, M., Beck, J., & Graichen, K. (2025). Aerodynamic neural network modeling for gradient-based model predictive flight control. In Proc. 33rd Mediterranean Conference on Control and Automation (MED 2025).

- Dio, M., Wahrburg, A., Enayati, N., Graichen, K., & Völz, A. (2025). Time-Optimal Path Parameterization with Viscous Friction and Jerk Constraints based on Reachability Analysis. In Proceedings of the 2025 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). Hangzhou, CN.

- Goller, T., Hopf, V., Völz, A., & Graichen, K. (2025). Fault Handling in Robotic Manipulation Tasks for Model Predictive Interaction Control. IEEE Robotics and Automation Letters, 10(9), 9002 - 9009. https://doi.org/10.1109/LRA.2025.3592069

- Hartmann, P., & Graichen, K. (2025). Learning-based uncertainty-aware predictive control of truck-trailer systems in rough terrain. In Institute of Electrical and Electronics Engineers (IEEE) (Eds.), Proceedings of the 19th IEEE International Conference on Control & Automation (ICCA). Tallinn (Estonia), EE.

- Kißkalt, J., Michalka, A., Strohmeyer, C., Horn, M., & Graichen, K. (2025). Estimation of input rotation speed in gauge-sensorized strain wave gears. In Proceedings of the 2025 IEEE Conference on Control Technology and Applications (CCTA). San Diego (USA).

- Kißkalt, J., Michalka, A., Strohmeyer, C., Horn, M., & Graichen, K. (2025). Model-based fault simulation and detection for gauge-sensorized strain wave gears. In IFAC-PapersOnLine (pp. 271 - 276). Vienna (Austria).

- Kowalewski, J., Lorenz, A., Thomas, F., Valenzuela, R.A.A., & Graichen, K. (2025). Passivity-Based Robust Stability Analysis of the Converter–Grid Interaction and Passivity-Shaping Controller Design. IET Generation Transmission & Distribution, 19(1). https://doi.org/10.1049/gtd2.70090

- Kruse, T., Griebel, T., & Graichen, K. (2025). Adaptive Kalman filtering: Measurement and process noise covariance estimation using Kalman smoothing. IEEE Access, 13, 11863-11875. https://doi.org/10.1109/ACCESS.2025.3528348

- Landgraf, D., Völz, A., & Graichen, K. (2025). A software framework for stochastic model predictive control of nonlinear continuous-time systems (GRAMPC-S). Optimization and Engineering. https://doi.org/10.1007/s11081-025-10006-z

- Landgraf, D., Wietzke, T., & Graichen, K. (2025). Stochastic model predictive control with switched latent force models. European Journal of Control, 85, 101311. https://doi.org/10.1016/j.ejcon.2025.101311

- Pierer von Esch, M., Nistler, E., Völz, A., & Graichen, K. (2025). Sensitivity-based distributed NMPC: Experimental results for a levitating planar motion system. IEEE Transactions on Control Systems Technology. https://doi.org/10.1109/TCST.2025.3530165

- Pierer von Esch, M., Völz, A., & Graichen, K. (2025). A fixed-point iteration scheme for sensitivity-based distributed optimal control. IEEE Transactions on Automatic Control, 70(4), 2778-2785. https://doi.org/10.1109/TAC.2024.3505753

- Pierer von Esch, M., Völz, A., & Graichen, K. (2025). Asynchronous sensitivity-based distributed optimal control for nonlinear systems. In Proceedings of the 2025 American Control Conference (ACC). Denver, CO (USA).

- Pierer von Esch, M., Völz, A., & Graichen, K. (2025). Sensitivity-Based Distributed Model Predictive Control for Nonlinear Systems under Inexact Optimization. Optimal Control Applications & Methods, (accepted).

- Rabenstein, G., Völz, A., & Graichen, K. (2025). Cable Manipulation for Contact Shaping Tasks using Elastic Rods. In Proceedings of the IEEE International Conference on Advanced Robotics and Mechatronics (ICARM). Portsmouth.

- Ren, Y., Deichsel, F., Hopf, V., Seiler, J., Kaup, A., & Beckerle, P. (2025). Networked Systems Diagnostics: A Fusion of Failure Mode and Effects Analysis and a Delphi Expert Study. In 2024 IEEE International Conference on Systems, Man, and Cybernetics (SMC) (pp. 2041-2046). Kuching, MY: Institute of Electrical and Electronics Engineers Inc..

- Santer, P., Reinhard, J., Schindler, A., & Graichen, K. (2025). Detection of localized bearing faults in PMSMs by means of envelope analysis and wavelet packet transform using motor speed and current signals. Mechatronics, 106. https://doi.org/10.1016/j.mechatronics.2025.103294

- Santer, P., Völz, A., & Graichen, K. (2025). A Model Predictive Control Approach to Trajectory Tracking with Human-Robot Collision Avoidance. In Proceedings of the 2025 IEEE Conference on Control Technology and Applications (CCTA). San Diego, US.

- Stecher, J., Kiltz, L., & Graichen, K. (2025). Generalized tolerance optimization for robust system design by adaptive learning of Gaussian processes. IEEE Access, (accepted).

- Südhoff, T., Hsuan-Yang, S., Villwock, J., Bliatsiou, C., Topalovic, D., Graichen, K.,... Knorn, S. (2025). Closed-loop control of a liquid-liquid mixer using MPC and GPR-models. In Proceedings of the 33rd Mediterranean Conference on Control and Automation (MED 2025). Tangier, Morocco, MA.

- Ullrich, L., Buchholz, M., Dietmayer, K., & Graichen, K. (2025). Expanding the Classical V-Model for the Development of Complex Systems Incorporating AI. IEEE Transactions on Intelligent Vehicles, 10(3), 1790-1804. https://doi.org/10.1109/TIV.2024.3434515

- Ullrich, L., Buchholz, M., Petit, J., Dietmayer, K., & Graichen, K. (2025). A Concept for Efficient Scalability of Automated Driving Allowing for Technical, Legal, Cultural, and Ethical Differences. In Proceedings of the 2025 IEEE 28th International Conference on Intelligent Transportation Systems (ITSC). Gold Coast (Australia).

- Ullrich, L., Mujirishvili, Z., & Graichen, K. (2025). Enhancing system self-awareness and trust of AI: A case study in trajectory prediction and planning. In Proceedings of the 36th IEEE Intelligent Vehicles Symposium (IEEE IV 2025). Cluj-Napoca (Romania).